5-axis CNC routers represent the highest level of precision, flexibility, and performance in modern machining. They can carve complex geometries, curved surfaces, and multi-sided parts — all in a single setup. But to unlock that power, you need the right CAM (Computer-Aided Manufacturing) software.

Not all CAM software supports full 5-axis motion, and choosing the right one can make or break your workflow. In this guide, we’ll explore what makes 5-axis CAM special, how it differs from standard tools, and which professional software delivers the best results. Whether you’re using a machine like the TwoTrees X5 5-Axis CNC Router or planning to upgrade soon, this comparison will help you find the right solution for your shop.

Why 5-Axis CAM Software Is Different

In a 5-axis setup, the cutting tool or the workpiece can move and rotate simultaneously across five different directions — typically X, Y, Z (linear) and A, B (rotational). This freedom allows the tool to approach the material from virtually any angle, minimizing repositioning and maximizing accuracy.

However, with greater motion comes greater complexity. 5-axis CAM software must handle:

- Tool orientation control: Managing the angle of the cutter for every move.

- Collision avoidance: Preventing tool, holder, or spindle crashes.

- Kinematic simulation: Accounting for real-world machine movement limits.

- Optimized toolpaths: Ensuring smooth, efficient cutting at variable angles.

Regular 3-axis or 4-axis CAM software can’t accurately compute these multi-directional paths. That’s why true 5-axis programming requires specialized tools that combine precision algorithms, simulation, and verification.

Top CAM Software for 5-Axis CNC Routers

Below are five of the most widely used professional CAM platforms for 5-axis machining — ranging from accessible maker-friendly software to enterprise-grade industrial suites.

Photo Credit: Autodesk Fusion 360:

Fusion 360 (Autodesk) — Best for Affordability and Accessibility

Ideal for: Small workshops, product designers, and prototyping studios.

Platform: Windows & macOS

Pricing: ~$545/year + optional Machining Extension for 5-axis operations.

Fusion 360 combines CAD, CAM, and simulation in a single platform. Its integrated environment makes it a favorite for makers and small businesses that need powerful 5-axis capability without enterprise-level cost.

Key Features

- Supports both 3+2 (indexed) and simultaneous 5-axis machining.

- Built-in adaptive clearing for efficient roughing and finishing.

- Realistic simulation and collision checking with the Machining Extension.

- Cloud collaboration and version control for team workflows.

Pros

- Affordable entry point for 5-axis machining.

- All-in-one CAD/CAM platform.

- Large community and extensive tutorials.

Cons

- Requires strong PC or GPU for large projects.

- Subscription-based; full 5-axis features need the paid extension.

Bottom line: Fusion 360 bridges the gap between hobby and professional 5-axis CAM, making it an excellent choice for workshops using routers like the TwoTrees X5.

PowerMill (Autodesk) — Best for Complex Surfaces and Mold Making

Ideal for: Aerospace, mold-making, and automotive applications.

Platform: Windows

Pricing: Enterprise-level (quote-based).

PowerMill is Autodesk’s high-end CAM software focused on advanced toolpath optimization. It’s built for professionals who need the utmost precision and control — often used in aerospace, automotive, and die/mold industries.

Key Features

- Dedicated 5-axis roughing and finishing strategies.

- Automatic collision checking and toolpath optimization.

- High-speed machining with smooth, efficient transitions.

- Customizable post-processors for complex machine kinematics.

Pros

- Unmatched precision for sculpted or freeform surfaces.

- Excellent machine simulation and verification tools.

- Handles large, complex toolpaths effortlessly.

Cons

- High cost and steep learning curve.

- Requires advanced understanding of 5-axis motion.

Bottom line: PowerMill is the choice for companies producing complex molds or aerospace-grade parts — the software of choice when every micron counts.

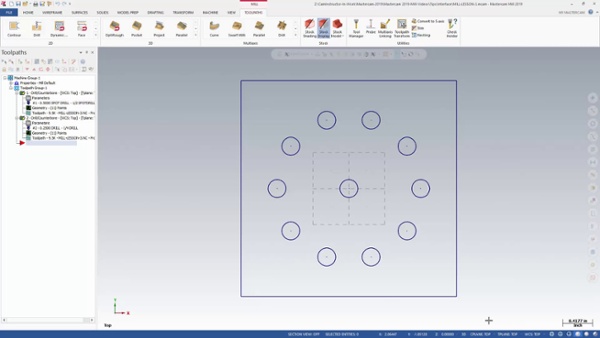

Photo Credit: Cam Instructor

Mastercam — Best for Industry-Standard 5-Axis Programming

Ideal for: Professional machinists and established CNC shops.

Platform: Windows

Pricing: Mid-to-high tier (perpetual or subscription).

Mastercam is one of the most recognized CAM platforms worldwide. It’s widely used in training centers and production shops, known for reliability, flexible licensing, and excellent post-processor compatibility.

Key Features

- Comprehensive 3+2 and simultaneous 5-axis machining support.

- Extensive post-processor library for most machine brands.

- Toolpath types: swarf, multiblade, flowline, and contour.

- Powerful simulation and material removal visualization.

Pros

- Highly adaptable and well-supported globally.

- Scalable from 3-axis to full 5-axis environments.

- Large library of verified machine definitions.

Cons

- Interface can feel dated compared to newer CAM platforms.

- Requires configuration for optimal 5-axis post-processing.

Bottom line: Mastercam is a proven workhorse that delivers consistent results across diverse 5-axis machines — from small routers to industrial mills.

HyperMill (OpenMind) — Best for Aerospace and Ultra-Precision Machining

Ideal for: Aerospace, defense, and high-value prototyping.

Platform: Windows

Pricing: Premium enterprise software.

HyperMill focuses on the most demanding multi-axis applications. Its algorithms generate exceptionally smooth, collision-free toolpaths with advanced finishing strategies tailored for freeform surfaces.

Key Features

- Automatic collision detection and tool-axis optimization.

- Specialized strategies for turbine blades, molds, and sculpted parts.

- Highly customizable interface and macros for repetitive jobs.

- Seamless integration with major CAD systems (SolidWorks, Siemens NX).

Pros

- Best-in-class accuracy for simultaneous 5-axis machining.

- Ideal for premium surface quality and tolerance control.

- Exceptional post-processor customization.

Cons

- Very high cost and requires experienced operators.

- Primarily targeted at enterprise and industrial markets.

Bottom line: HyperMill is the gold standard for precision machining. If your work demands perfection in every contour and curve, this is your software.

SolidCAM — Best for SolidWorks Users and Integrated CAD Workflows

Ideal for: Design engineers and small manufacturing teams.

Platform: Windows

Pricing: Mid-to-high tier, license-based.

SolidCAM integrates directly into SolidWorks and Autodesk Inventor, creating a seamless CAD-to-CAM pipeline. It supports both indexed and full 5-axis toolpaths without needing file transfers or external interfaces.

Key Features

- Full 5-axis simultaneous and indexing support.

- Powerful simulation and collision checking inside SolidWorks.

- Advanced control over tool orientation and machining sequences.

- Modular upgrades for turning, milling, and HSM toolpaths.

Pros

- Native CAD integration for fast updates and revisions.

- Good balance of performance and usability.

- Ideal for engineering teams already using SolidWorks CAD.

Cons

- Requires SolidWorks or Inventor license.

- Less powerful in specialized freeform machining than PowerMill or HyperMill.

Bottom line: SolidCAM is perfect for design-driven teams who want high-end CAM within the environment they already use daily.

Comparison Table: Top 5 CAM Tools for 5-Axis CNC Routers

| Feature | Fusion 360 | PowerMill | Mastercam | HyperMill | SolidCAM |

|---|---|---|---|---|---|

| Best For | Small shops / makers | Complex surfaces & molds | Industry standard machining | Aerospace / precision tooling | SolidWorks integration |

| 5-Axis Type | 3+2 + Simultaneous | Full Simultaneous | Full Simultaneous | Full Simultaneous | 3+2 + Simultaneous |

| Ease of Use | Easy–Moderate | Advanced | Moderate | Advanced | Moderate |

| Simulation & Collision | Yes | Advanced | Yes | Advanced | Yes |

| Integration | Built-in CAD/CAM | Autodesk Suite | Standalone | Standalone | SolidWorks / Inventor |

| Pricing Tier | $$ | $$$$ | $$$ | $$$$ | $$$ |

Choosing the Right 5-Axis CAM Software

The best CAM platform depends on your workflow, material type, and budget:

- For Makers and Small Workshops: Fusion 360 offers the easiest entry into 5-axis machining without sacrificing performance.

- For Industrial Mold and Aerospace Work: PowerMill and HyperMill provide unmatched precision and control for complex geometries.

- For Established Manufacturing Shops: Mastercam remains the most versatile and widely supported option.

- For CAD-Driven Workflows: SolidCAM is ideal if your team already uses SolidWorks or Inventor.

No matter which software you choose, make sure it supports your machine’s post-processor and kinematics. A well-matched CAM setup ensures your router performs to its full potential.

Pairing Software with the Right 5-Axis Router

Even the best CAM software needs capable hardware to bring toolpaths to life. The TwoTrees X5 5-Axis CNC Router is designed for makers and professionals seeking industrial-grade precision at a more accessible price point. It supports advanced 5-axis post-processors from all major CAM platforms, including Fusion 360, PowerMill, and Mastercam.

- Work envelope: Large format ideal for complex parts.

- Rigid frame: High stability for accurate multi-axis machining.

- Compatibility: GRBL-based control compatible with standard G-code outputs.

By pairing software like Fusion 360 or PowerMill with the TwoTrees X5, creators can achieve world-class precision without the six-figure investment typical of industrial 5-axis machines.

Conclusion

5-axis machining opens a world of creative and manufacturing possibilities — but only when paired with the right software. Tools like Fusion 360 make advanced CAM accessible to small shops, while PowerMill, Mastercam, and HyperMill dominate the professional arena.

Whether you’re machining complex molds or designing custom prototypes, your CAM software is what transforms your ideas into motion. And with machines like the TwoTrees X5, advanced 5-axis capabilities are now within reach for makers everywhere.

Ready to Master 5-Axis Machining?

Explore how the TwoTrees X5 5-Axis CNC Router pairs with your preferred CAM platform to create advanced, multi-sided, and high-precision projects. Upgrade your workshop with professional 5-axis control and discover what’s possible when cutting-edge software meets exceptional hardware.

👉 View Product Details